Premium Automotive Aftermarket Parts Provider Improves Production Yield with Moldex3D Simulation Solution

Â

- Customer:Â TYC Brother Industrial Co., Ltd.

- Region: Taiwan

- Industry:Â Automotive

- Solution:Â Moldex3D Advanced

- View PDF Version

Executive Summary

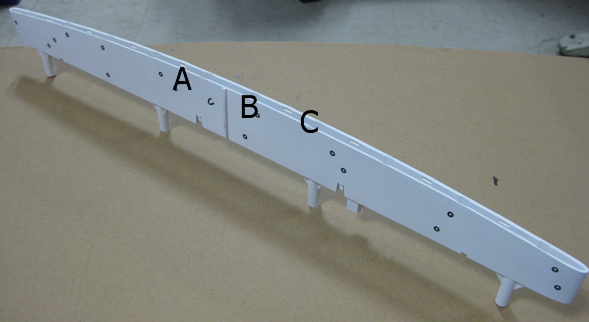

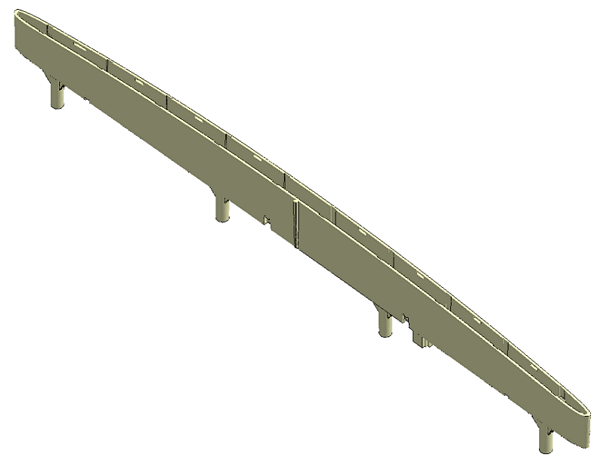

A third brake light is an effective alert to warn following drivers to slow down. It can help shorten the brake reaction time and reduce up to 50% of rear-end collisions, making it an indispensable gadget in almost every car. The concept of having a slimmer and longer third brake light design has grown increasingly popular in the contemporary lighting design for a vehicle. However, with this kind of design, it poses a difficult manufacturing challenge. Due to the narrow-gap design in the central area of the light base, it is hard to control the heat dissipation inside the cavity. In this case, the unbalanced heat dissipation caused a shrinkage problem, thereby leading to troublesome product deformation and assembly issues. TYC utilized Moldex3D plastic injection molding simulation solution to assess the shrinkage problem and was able to find the most feasible solution to resolve this problem successfully. Thus, the ultimate goal: saving time, reducing cost, and improving the product yield rate could be achieved.

|

|

Fig. 1  Third Brake Light |

Fig. 2  Part Design |

Challenges

- Achieve more than 30% improvement in product shrinkage

- Reduce assembly time

- Expedite time-to-market

Benefits

- Achieved 57.4% improvement in product shrinkage

- Improved yield rate from 62.7% to 98.2%

- Reduced part assembly time was from 434 seconds to 257 seconds.

Case Study

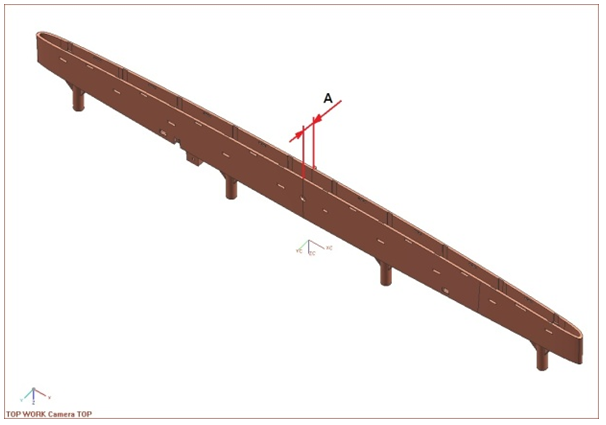

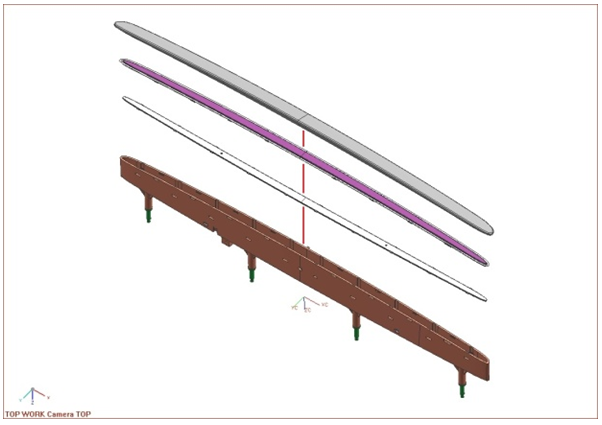

Due to the unique narrow-gap design, a shrinkage problem was likely to occur in a real-life molding process (see Fig. 3, Point A). The shrinkage may not only affect the product appearance, but cause a substantial difficulty when assembling the light case and the light base together (see Fig. 4) which later may lead to a greater challenge in light-guide devices and LED circuit boards assembly.

|

Fig.3  The light base |

Fig.4  Assembly sequence of a third brake light |

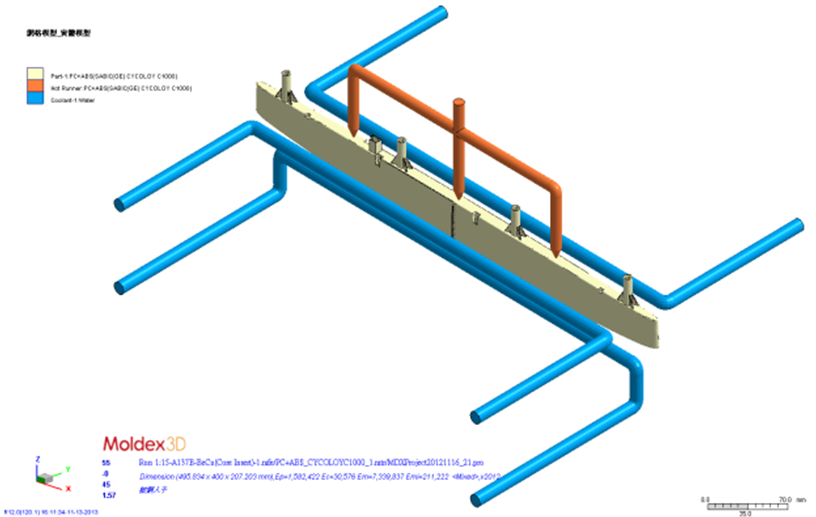

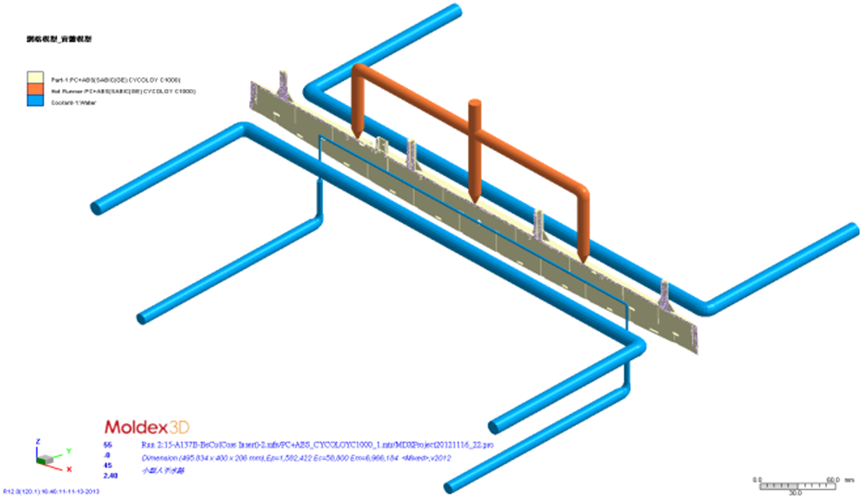

In the original design, the main factor that contributed to product deformation was the uneven mold temperature which resulted in severe shrinkage around the central area of the part. In order to balance the heat dissipation and improve product shrinkage, two design changes for better cooling purpose were proposed and further studied:

1. Replace the material of the part insert from P-5 steel to beryllium copper (Fig. 5(b))

2. Add a 3mm cooling channel in the P-5 steel part insert (Fig. 5(c))

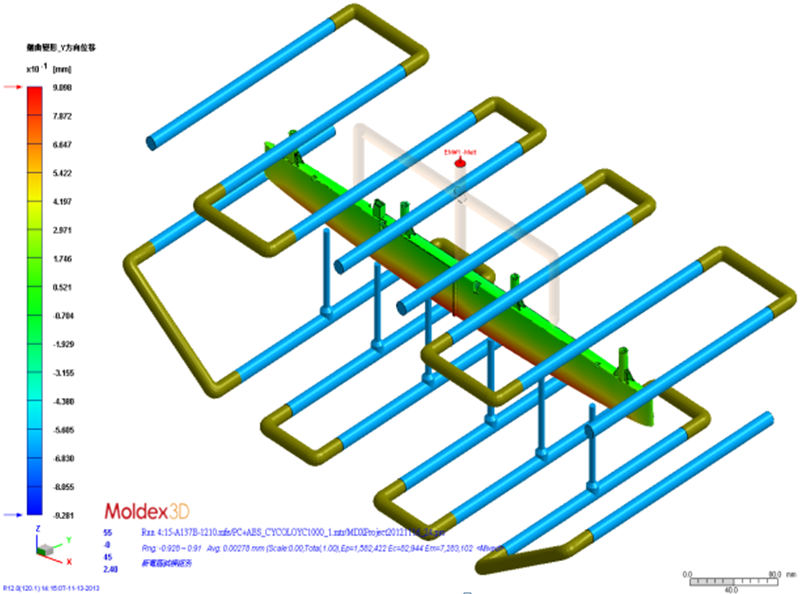

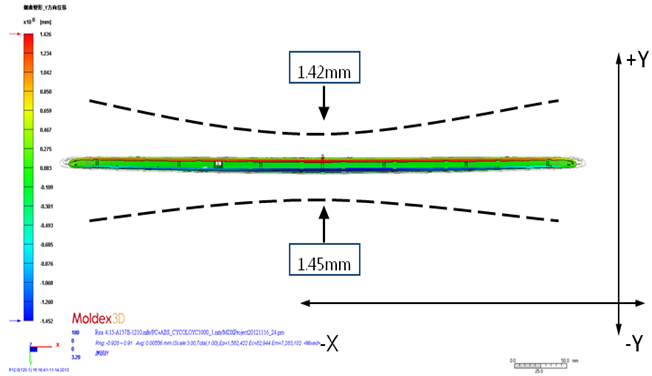

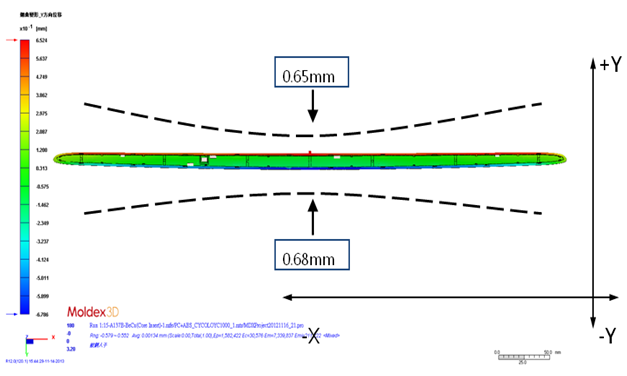

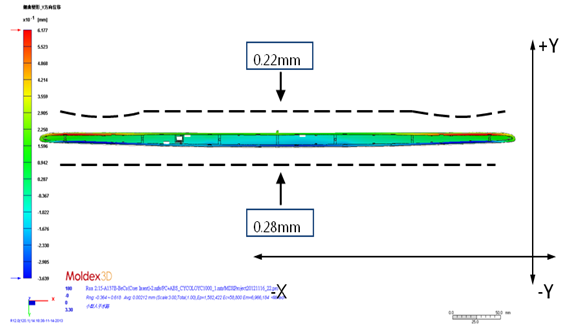

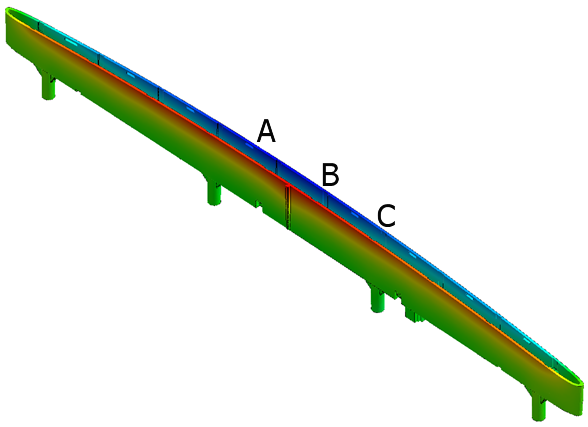

The biggest displacement appeared on the two ends of the product, and the shrinkage occurred in the center of the product (Fig. 6(a)). However, according to Moldex3D simulation results of the above proposed design changes, the unbalanced heat dissipation and Y-displacement were both improved in Design 1 (Fig. 6(b)); while the improvements were even more significant in Design 2 (Fig. 6(c)). Thus, Design 2 could be regarded as a better optimization option.

|

|

|

Fig. 5  (a) The original design |

Fig. 5 Â (b) Design change 1Â |

Fig. 5  (c) Design change 2 |

|

Â Â |

|

Fig. 6  (a) The original design: Y-displacement |

Fig. 6  (b) Design change 1: Y-displacement |

Fig. 6  (c) Design change 2: Y-displacement |

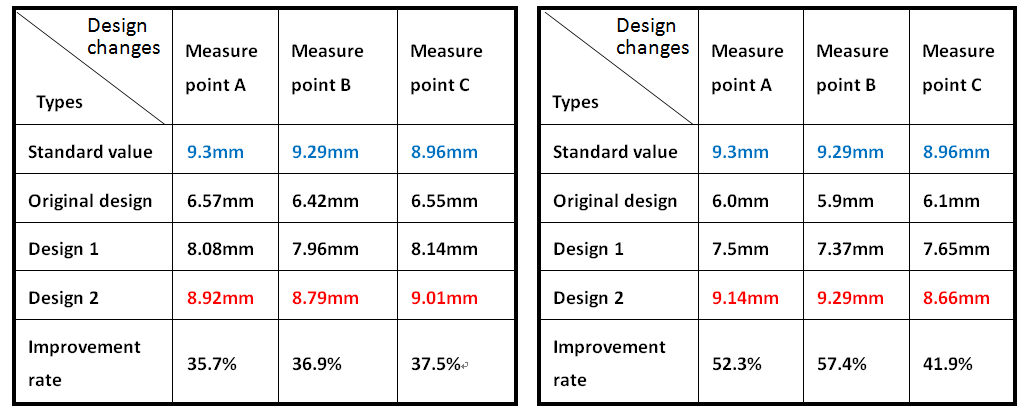

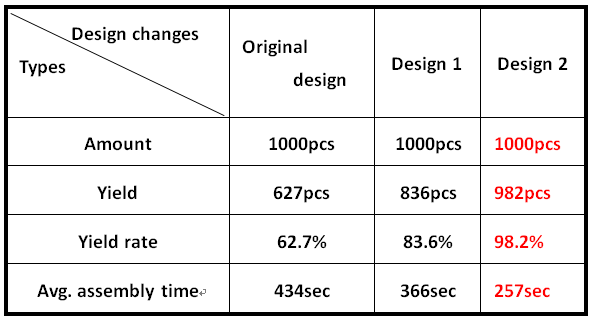

In addition, the comparison between the Moldex3D simulation analysis and the real-life molding results also indicated that Design 2 performed the best cooling efficiency among the three designs. Through an actual experiment of assembling 1000 pieces of real parts produced, based on each design (Fig. 7(a) and Fig.7(b)), Design 2 achieved an outstanding 57.4% improvement in product shrinkage and the yield rate was improved to 98.2% (Table1 & 2). Moreover, the average time required for part assembly was reduced from 434 seconds to 257 seconds. In summary, Moldex3D was able to provide accurate simulation results and successfully helped TYC optimize the cooling system to effectively resolve the shrinkage defect and further improve the product quality.

Â

|

Fig. 7  (b) The real product |

Table 1 Â The comparison between Moldex3D simulation analysis and the real-life molding results

Table 1 Â The comparison between Moldex3D simulation analysis and the real-life molding results

Table 2 Â The comparison of yield rates and the required assembly time for three different designs

Table 2 Â The comparison of yield rates and the required assembly time for three different designs

Results

Through Moldex3D plastic injection molding simulation analysis, TYC was able to clearly understand that the mold temperature has a direct impact on product shrinkage. And, with the help of Moldex3D simulation solution, the shrinkage volume was successfully reduced by a significant amount and the product yield rate was substantially improved to be over 98% which both contributed to achieving its goal of time and cost reduction. This case perfectly demonstrated the close correlation of Moldex3D simulation analysis with real-life molding scenario and proved that Moldex3D simulation solution can be a useful tool and reliable reference for TYC’s future product development.

Heat Sink For Module,Aluminum Heat Sink,Aluminum Radiator Sink,High Power Aluminum Radiator

Suzhou AME Aluminum Product Co.,Ltd , https://www.ame-al.com

Â Fig. 7 Â (a) Moldex3D simulation analysis

Fig. 7  (a) Moldex3D simulation analysis