SMPI Uses Moldex3D to Accurately Predict Product Problems

SHENG MEI PRECISION INDUSTRIAL (SMPI)Â values every single technique in the production process. We highly value teamwork and independent research and development. With year-long management experience, we believe high quality is the key to business success and continuity. Our product quality control begins with the research development stage. Strict quality control is carried out with inspection equipment to prevent customers from receiving defective products and helps us gain positive feedback from customers.

Project Summary

As we live in the age of information, laptops are found in almost every household. Given the rapid pace of new development in computers, mold makers are exploring every possibility to shorten cycle times. As the rising international oil price drives up the costs of polymers, mold tryouts become costly to businesses. The need for an alternative to this trial and error method is essential for reducing development cost and time. Therefore, Moldex3D, the computer-assisted engineering software, is growing in popularity with mold and part designers. The case study presented here demonstrates how simulation analysis can minimize the difference between partial and overall wall thickness and further improve dimensional difference and warpage problems.

Challenges

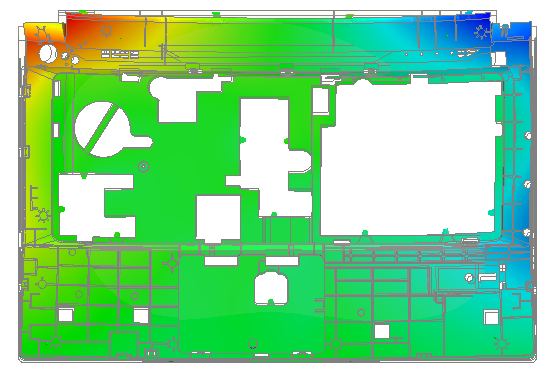

As the advancement of technology, laptop designs are becoming thinner and lighter by reducing the body thickness to meet easy portability needs. In some cases when we need to consider other product factors, wall thickness can increase in some areas while decreasing overall, and this is how wall thickness difference occurs. The difference often causes dimensional difference and warpage problems.

Solutions

In the early days, time and money spent on mold trials kept rising since the molding machine operators had to ensure product quality and meet customer demand through the process of fine-tuning parameters. Design changes are required if the problem cannot be solved by performing machine adjustments. However, this may result in additional mold trial costs and even delay time-to-market. Dimensional difference and warpage have been the serious real-world molding problems. With help from Moldex3D, the leading computer assisted engineering software, mold makers can easily investigate potential defects and fix them in advance.

Benefits

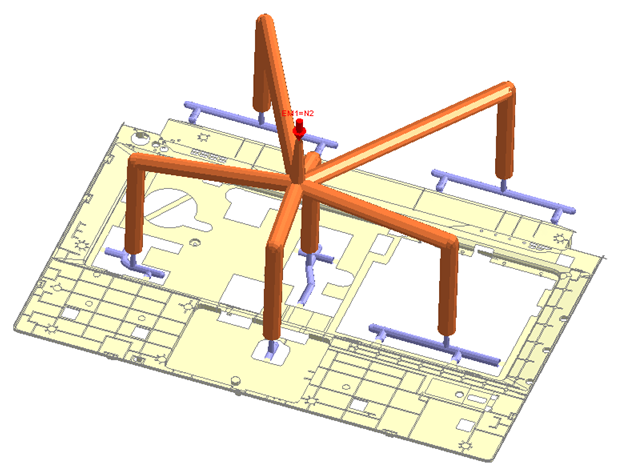

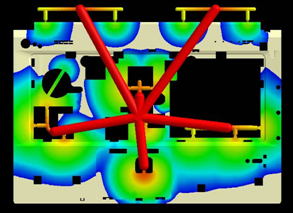

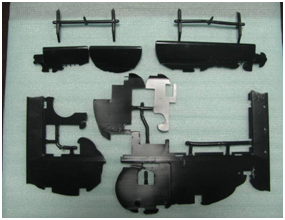

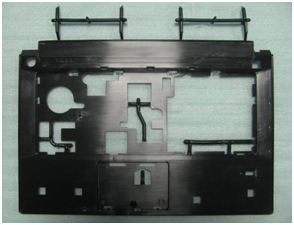

Using Moldex3D software, SMPI performed the part thickness variations analysis for the top cabinet of the notebook and effectively solved dimensional difference and warpage problems. This not only improves the product quality but also saves the time and costs on mold trials. Meanwhile, it also helps find out that it is more effective to solve many molding problems in advance by taking product designing phase into consideration.

Results

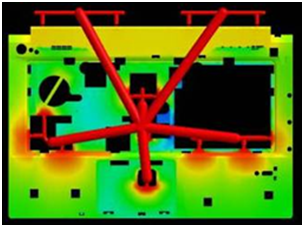

Since high-gloss parts demands extremely high surface quality, heat and cool process is implemented to ensure the surface quality and avoid shrinkage problem. Through analysis, we can predict the part thickness variations arisen with part thickness variations, large displacement, dimensional control, and severe dimensional difference. Uneven volumetric shrinkage will affect dimensional stability to a great extent; therefore, it is necessary to change the wall thickness in certain areas to improve the uneven volumetric shrinkage and effectively solve dimensional difference problem.

Â

Â

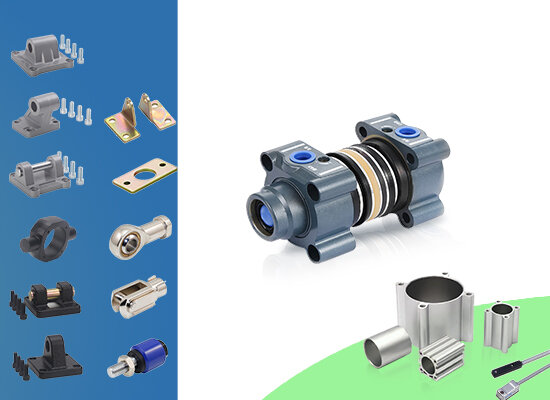

Pneumatic Cylinder Accessories

Air cylinder accessories of different models and different standards are generally not interchanged. When ordering Pneumatic Cylinder accessories, please note the specifications and parameters of the corresponding cylinder. If the standard and model of the cylinder are same, the cylinder accessories can be used interchangeably.Pneumatic Cylinder Tube.

Pneumatic cylinder is the executing component in pneumatic systems, mainly used to convert the pressure energy of compressed air into mechanical energy, generating linear or oscillatory motion. The construction of pneumatic cylinders is complex and includes multiple key components. Below are some common components and their functions:

Cylinder Barrel: This is the main body of a cylinder, typically a cylindrical container used to accommodate pistons and other internal components. The cylinder barrel must be strong enough to withstand the pressure of compressed air inside.

Piston: located inside the cylinder and in close contact with the inner wall of the cylinder barrel. When compressed air enters the cylinder, the piston moves inside the cylinder barrel, generating thrust or tension.

Piston Rod: The part that connects the piston to the external mechanical structure and is used to transmit the linear motion of the piston.

End caps/caps: fixed at both ends of the cylinder barrel, sealing the internal space of the cylinder and supporting the piston rod and other components. The front cover usually includes a guiding component for the piston rod.

Seals: Used to prevent gas leakage and ensure smooth movement of the piston within the cylinder barrel. It mainly includes piston sealing rings, rod sealing rings, and dust sealing rings.

Guide bushing: Helps the piston rod maintain the correct direction of movement, reducing friction and wear.

Buffer Device: Some cylinders are equipped with buffer devices to slow down the speed of piston movement when it reaches the end point, preventing impact and noise.

Magnetic switches: Some cylinders have built-in or external magnetic switches used to detect the position of the piston and control the action of the cylinder.

Exhaust Flow Control Valve: Sometimes integrated into the cylinder, it is used to regulate the exhaust speed and control the speed of the piston.

These components work together to enable the pneumatic cylinder to effectively convert the energy of compressed air into the required mechanical motion. According to specific application requirements, pneumatic cylinders may also include other specially designed components to meet specific functional requirements.

Pneumatic Cylinder Accessories,Pneumatic Cylinder Parts

Foshan Weiyingjia Technology Co., Ltd , https://www.wyspneumatic.com